Automobile

When auto parts, including engines, wheels, and other auto parts are sent from various places to assembly plants, a large amount of EPE, EPP, and EPS packaging materials are needed to protect the safe transportation of the parts. Upon arrival at the assembly plant, the packaging must be handled, and some countries require a processing fee to be paid for the disposal of discarded packaging. Because foam is very light in density and large in size, the processing fee is expensive.

In response to this industry pain point, GREENMAX has developed compression equipment for waste foam processing in the automotive industry. Compressing the waste foam and then carrying out subsequent processing not only reduces the processing cost, but also the compressed waste can be resold.

According to research by Future Market Insights, the global EPE packaging market is expected to increase from US$1.4 billion to US$2.1 billion in 2023. Multiple industries tend to use this versatile and environmentally friendly material. Many precision auto parts are also protected by EPE foam packaging. In order to better realize the recycling of EPE foam, the well-known automobile company Tesla cooperated with GREENMAX.

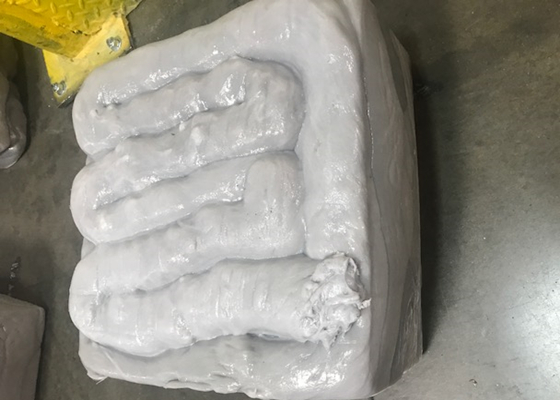

EPE foam is more flexible than EPS, so more people choose to use hot melting technology for recycling to better compress EPE. The GREENMAX foam densifier heats and melts EPE, which will be converted into compact foam ingots at the ratio of 90:1. Tesla started a foam recycling project a long time ago. In order to find a foam recycling machine with better performance and recycle EPE, the team established a cooperative relationship with GREENMAX.

GREENMAX first had an in-depth understanding of Tesla’s foam recycling needs, including foam density, output and other indicators. Then, GREENMAX will design the waste foam recycling solution that best suits Tesla's needs.