What we want is more than just equipment

“When we decided to promote foam recycling in Oregon, the challenges were far more complex than we imagined.” Before launching a structured program, CAA relied mainly on landfilling. A few facilities accepted discarded foam, but overall foam recycling efficiency was low—and the system was difficult to scale.

The challenge: scattered drop-off points, transport limits, and compliance pressure

CAA faced a familiar problem in foam recycling: collection points were dispersed, transport distances were limited, and handling methods were constrained by local rules. In practice, loose EPS is bulky and costly to move. Where regulations restrict long-distance hauling of low-density material, a program can stall before it starts.

Landfilling was also a strategic dead-end. Extended Producer Responsibility (EPR) requirements push brands to take back discarded packaging materials, which increasingly ties into corporate ESG goals. CAA needed a solution that could operate long-term—not a temporary workaround.

Why GREENMAX: engineering the system first, then the machine

CAA found GREENMAX through an online search while exploring options for foam recycling. At first, the team looked mainly at cold-pressing equipment. But instead of immediately pushing a product, GREENMAX engineers shared reference projects: how different regions handle regulatory constraints, how collection and processing can be designed, and how end-markets can be supported to close the loop.

As the research deepened, CAA's focus shifted from “Which machine should we buy?” to “Can we build a replicable, traceable foam recycling system that regulators and brand partners can trust?” That’s where the collaboration became a program design exercise—not just an equipment purchase.

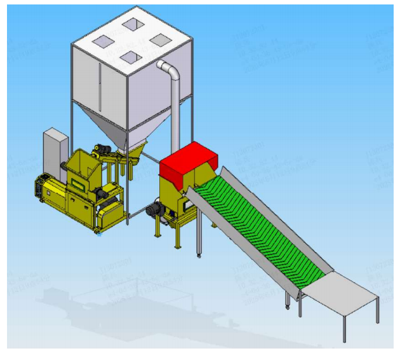

The solution: a custom M-C300 foam densifier designed for EPS + EPE

CAA ultimately selected a foam densifier that differed significantly from the first concept. The GREENMAX M-C300 is a larger, customized model built around the client’s operating reality. It features separate crushing and feeding chambers, helping save space and labor while supporting continuous processing.

Key design features that supported foam recycling at scale

- Large-format M-C300 foam densifier with separate crushing + feeding chambers for workflow efficiency.

- Material flexibility: quick switching between EPS and EPE, enabling multi-site operations with mixed inbound streams.

- Vehicle-mounted independent crushing design for mobile handling across different collection locations.

From concept to operation: validating the network model

After more than a year of discussions, validation, and detailed tuning, a compliant foam recycling approach took shape—connecting multiple collection points with centralized processing and a clear operational pathway. For CAA, the biggest win was reducing uncertainty: less dependence on inconsistent third-party pickup capacity, and more control over how foam is handled, densified, and documented.

Results: fewer headaches, clearer accountability, and a repeatable playbook

According to the project lead, the most valuable part wasn’t just the equipment quality—it was the model behind it. By aligning equipment choice with collection realities and regulatory constraints, CAA gained a path to expand foam recycling without constantly redesigning the process from scratch.

Project lead (CAA):

“What impressed us wasn’t only the equipment, but the recycling model—reducing unnecessary trouble and making reuse achievable.”

Key takeaways for PROs and recycling programs

- Treat foam recycling as a network problem (collection → transport → processing), not a single-machine decision.

- Densifying EPS early can be the difference between “pilot” and “scalable.”

- Design for mixed streams: a foam densifier that can handle EPS + EPE helps real-world operations.

- Mobile capability can unlock coverage when drop-off points are dispersed.

FAQ

What is a foam densifier used for in foam recycling?

A foam densifier reduces the volume of low-density foam (like EPS), making storage and transport more practical and cost-effective.

Can one foam densifier process both EPS and EPE?

Yes—this project used a custom GREENMAX M-C300 foam densifier designed to switch between EPS and EPE as inbound streams change.

Why did CAA need a custom design?

Because operational constraints (multiple sites, labor efficiency, and compliance) required a workflow-focused layout and mobile handling features.

How do you start building a scalable foam recycling program?

Map collection points, quantify volumes, check transport constraints, define compliance requirements, and then choose equipment that fits the full system.

Talk to GREENMAX about your foam recycling system

If you're designing an EPR-ready foam recycling program—especially with dispersed collection points—share your volumes, materials (EPS/EPE), and compliance constraints. GREENMAX can recommend a foam densifier configuration that fits your operating model.